Refrigerant Recovery

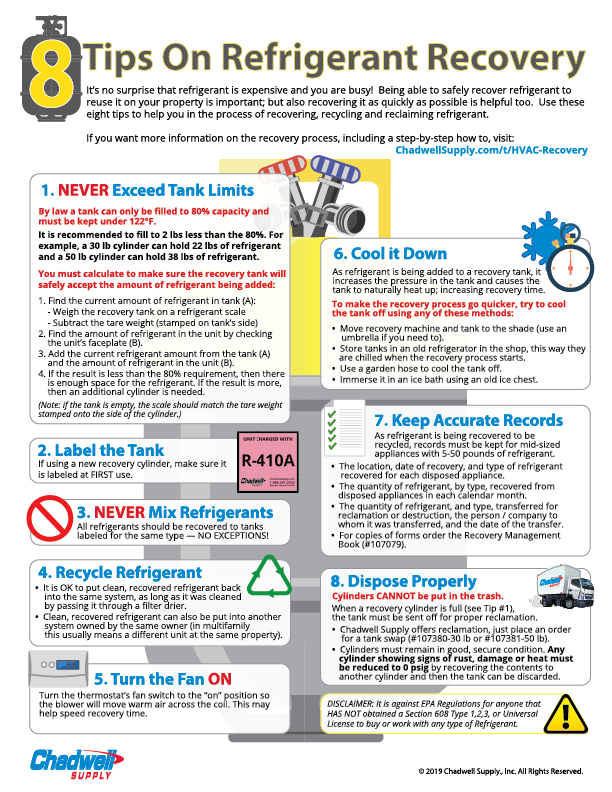

8 Tips on Refrigerant Recovery

It’s no secret that refrigerant is expensive and you are busy! Being able to safely recover refrigerant to reuse it on your property is important, but also recovering it as quickly as possible is helpful too. Use these eight tips to help you in the process of recovering, recycling and reclaiming refrigerant.

1. NEVER Exceed Refrigerant Recovery Tank Limits

By law, a tank can only be filled to 80% capacity and must be kept under 122°F.

It is recommended to fill to 2 lbs less than the 80%. For example, a 30 lb cylinder can hold 22 lbs of refrigerant and a 50 lb cylinder can hold 38 lbs of refrigerant.

You must calculate to make sure the recovery tank will safely accept the amount of refrigerant being added:

- Find the current amount of refrigerant in tank (A).

- Weigh the recovery tank on a refrigerant scale.

- Subtract the tare weight (stamped on tank’s side).

- Find the amount of refrigerant in the unit by checking the unit’s faceplate (B)

- Add the current refrigerant amount from the tank (A) and the amount of refrigerant in the unit (B).

- If the result is less than the 80% requirement, then there is enough space for the refrigerant. If the result is more, then an additional cylinder is needed.

(Note: if the tank is empty, the scale should match the tare weight stamped onto the side of the cylinder.)

2. Label the Recovery Tank

If using a new recovery cylinder, make sure it is labeled at FIRST use.

3. NEVER Mix Refrigerants

All refrigerants should be recovered to tanks labeled for the same type — NO EXCEPTIONS!

4. Recycle Refrigerant

It is OK to put clean, recovered refrigerant back into the same system, as long as it was cleaned by passing it through a filter drier. Clean, recovered refrigerant can also be put into another system owned by the same owner (in multifamily this usually means a different unit at the same property).

5. Turn the Fan ON

Turn the thermostat’s fan switch to the “on” position so the blower will move warm air across the coil. This may help speed recovery time.

6. Cool it Down

As refrigerant is being added to a recovery tank, it increases the pressure in the tank and causes the tank to naturally heat up; increasing recovery time.

To make the recovery process go quicker, try to cool the tank off using any of these methods:

- Move recovery machine and tank to the shade (use an umbrella if you need to).

- Store tanks in an old refrigerator in the shop, this way they are chilled when the recovery process starts.

- Use a garden hose to cool the tank off.

- Immerse it in an ice bath using an old ice chest.

7. Keep Accurate Records

As refrigerant is being recovered to be recycled, records must be kept for mid-sized appliances with 5-50 pounds of refrigerant.

- The location, date of recovery, and type of refrigerant recovered for each disposed appliance.

- The quantity of refrigerant, by type, recovered from disposed appliances in each calendar month.

- The quantity of refrigerant, and type, transferred for reclamation or destruction, the person/company to whom it was transferred, and the date of the transfer.

- For copies of forms order the Recovery Management Book (#107079).

8. Dispose Properly

- Cylinders CANNOT be put in the trash. When a recovery cylinder is full (see Tip #1), the tank must be sent off for proper reclamation.

- Chadwell Supply offers reclamation, just place an order for a tank swap (#107380-30 lb or #107381-50 lb).

- Cylinders must remain in good, secure condition. Any cylinder showing signs of rust, damage or heat must be reduced to 0 psig by recovering the contents to another cylinder and then the tank can be discarded.

Step-by-Step Refrigerant Recovery Process

Knowing how to properly recover refrigerant is a requirement enforced by the EPA in their efforts to protect the environment from the improper discharge of these chemicals. In this video tutorial, Chadwell University Instructor, Vann Flippen, walks through how to properly recover refrigerant on your property. For more information about HVAC and EPA608 classes review our class schedule for Chadwell University.

DISCLAIMER: It is against EPA Regulations for anyone that HAS NOT obtained a Section 608 Type 1,2,3, or Universal License to buy or work with any type of Refrigerant.